Custom Cylinder Brushes

Rotary brushes, also known as cylinder brushes, are designed in various styles such as spiral or paddle-wheel to perform a range of functions. These brushes are typically mounted onto a shaft and motorized to spin at high speeds, enhancing their brushing efficiency. Industrial rotary brushes are constructed using a strong, lightweight, and balanced polymer tube to ensure durability and performance.

Featuring bristles surrounding the inner core, rotary cylinder brushes can be fabricated in different sizes and with a variety of bristle materials. Commonly used materials include carbon steel, nylon, brass, polypropylene, and natural filaments such as horsehair or hog bristle. The bristles can be attached to the core through various methods, such as stapling, gluing, or hand-tying.

Cylinder Brushes Specifications

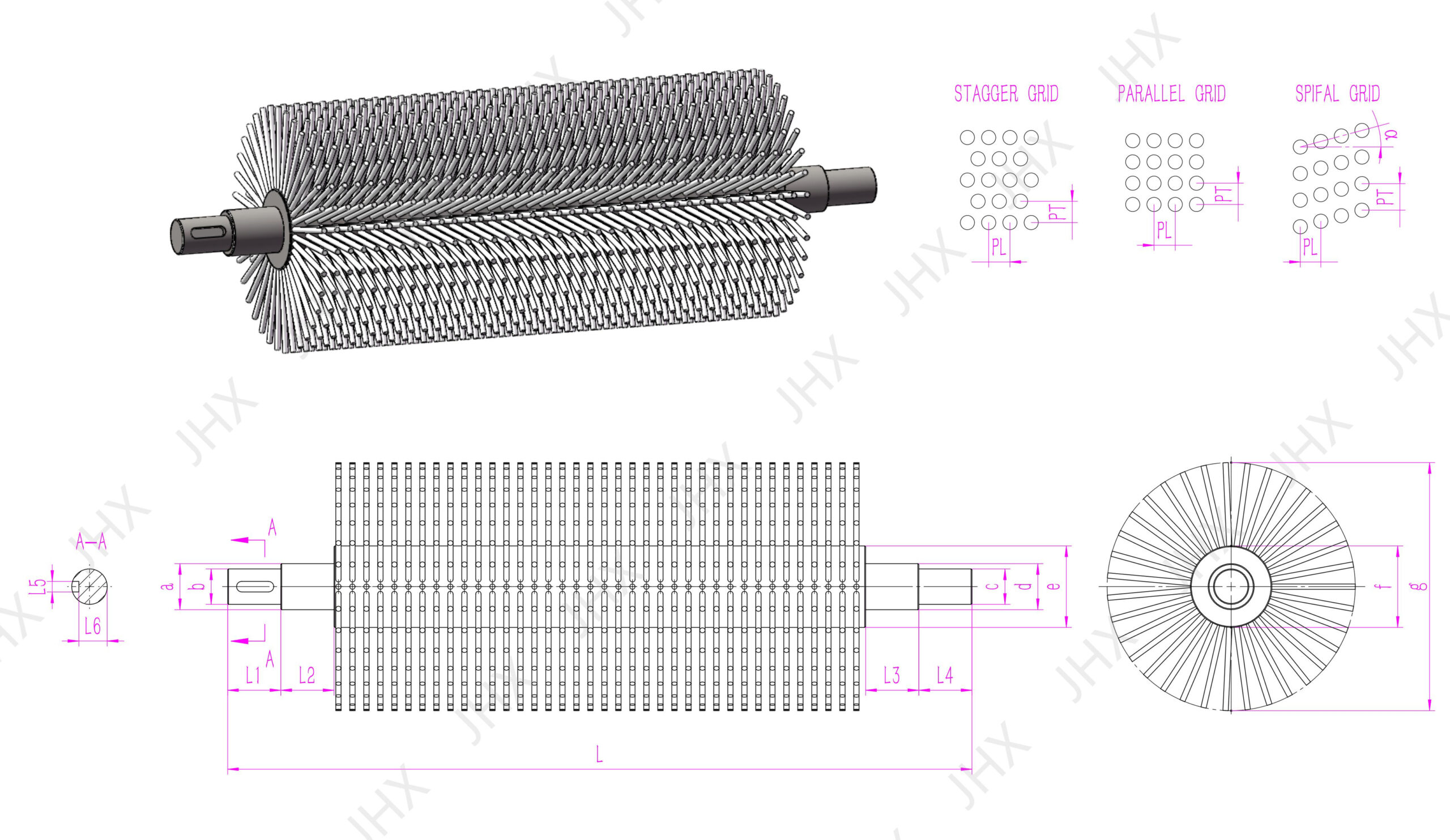

JHX specializes in providing custom cylinder brushes tailored to meet your specific needs. Cylinder brushes come with various parameters that allow you to customize them according to your specific application needs.

Brush Information

| Brush Face Length | This parameter refers to the length of the brush’s working surface, which determines its coverage. | 50mm-5000mm |

| Brush Diameter (OD) | The brush diameter, also known as the outer diameter (OD), affects the overall size and the area it can cover in a single pass. | 50mm-800mm |

| Fill Material Type | The fill material is the type of bristle used in the brush. Each material has its unique properties and is best suited for particular applications. | Nylon, pp, Brass, Metal, Horse Hair, Aluminum oxide, Silicon carbide |

| Fill Diameter | The fill diameter refers to the thickness of individual bristles. It can impact the brush’s stiffness and durability. | 0.05 mm-3mm |

Core Information(Option)

| Plastic Core Material | The core material is the central part of the brush that supports the bristles. Each material has its unique properties, such as chemical resistance, strength, and temperature tolerance. | PVC, polypropylene, and nylon |

| Core Length | The core length refers to the length of the brush’s inner structure, excluding the bristles. | The appropriate core length will depend on the intended brush face length and the required coverage. |

| Core Diameter | The core diameter refers to the thickness of the brush’s inner structure. The right core diameter depends on the desired brush diameter (OD) and the strength required for the specific application. | 15mm-300mm |

| Core ID / Arbor Hole Diameter | The core ID, or arbor hole diameter, is the diameter of the hole in the center of the brush that accommodates the shaft or mandrel. | 5mm-100mm |

| Tuft Hole Pattern | The tuft hole pattern refers to the arrangement of holes on the core, where the bristles are inserted. | The choice of the pattern depends on the desired brushing action, coverage, and efficiency. |

| Tuft Hole Size/Diameter | The tuft hole size, or diameter, is the size of the holes in the core where bristles are inserted. | 1.5mm-10mm |

| Tuft Hole Spacing (Center to Center) | Tuft hole spacing refers to the distance between the centers of adjacent tuft holes in the core. Spacing can vary depending on the desired brush density and performance. | 3mm-30mm |

Design Your Cylinder Brushes

Cylinder Brushes Types

Spiral-wound Cylinder Brushes: These brushes consist of brush filament wound around a core in a spiral pattern. The core can be made from various materials such as plastic, wood, or metal. They provide uniform pressure distribution and are ideal for cleaning, deburring, or polishing applications.

Staple-set Cylinder Brushes: In this type, brush filaments are stapled into a cylindrical core, typically made of wood, plastic, or metal. The filaments can be arranged in various patterns to suit specific applications, such as helical, herringbone, or straight-line patterns. They are commonly used for scrubbing, cleaning, and dust removal.

Tufted Cylinder Brushes: These brushes feature tufts of filaments that are individually anchored into a cylindrical core. This design allows for flexibility in filament arrangement, density, and pattern. Tufted cylinder brushes are suitable for applications like surface finishing, polishing, and cleaning.

Wire Cylinder Brushes: Wire cylinder brushes feature metal wire bristles, typically made from steel, brass, or stainless steel. These brushes are highly effective at removing rust, scale, and other debris from metal surfaces, making them ideal for aggressive cleaning and surface preparation tasks.

With our expertise and experience, we can customize the brush parameters, such as core material, bristle type, and brush dimensions, to ensure optimal performance for your specific application.

Cylinder Brushes Fill Material

Brush filling material refers to the type of bristles or fibers used in a brush. These materials can be natural, like animal hair or vegetable fibers, or synthetic, like nylon or polypropylene. The choice of brush filling material depends on the specific application and desired properties, such as stiffness, abrasion resistance, heat resistance, and chemical compatibility. Different brush filling materials offer various benefits and are suitable for a wide range of cleaning, scrubbing, or polishing tasks.

We provide a wide range of brush-filling materials to accommodate most applications. Plus, we also directly supply the brush filling, and if needed, we can perform basic processing like cutting it to the desired size. This way, our customers can conveniently work with the brush filling as soon as they receive it.

Application & Environment

Conveyor Cleaning: Cylinder brushes, often with nylon or polypropylene bristles, are used to clean conveyor belts in industries such as food processing, packaging, and material handling. They are mounted above or below the conveyor belt, spinning in the opposite direction to remove dust, debris, and product residue. Common parameters include brush face lengths corresponding to the conveyor width and appropriate bristle stiffness for effective cleaning without damaging the belt.

Surface Finishing: In metalworking and woodworking, cylinder brushes with abrasive or non-abrasive bristles (e.g., carbon steel, brass, or nylon) are used for deburring, polishing, and finishing surfaces. The brushes are often mounted on grinding or polishing machines, spinning at high speeds to provide consistent surface treatment. Key parameters include brush diameter, bristle material, and bristle density for desired surface finish quality.

Food Processing: Food-grade cylinder brushes, typically made with FDA-compliant materials like polypropylene or nylon, are used for cleaning and processing food items. They can be found in applications such as washing fruits and vegetables, moving products along conveyor lines, or cleaning equipment surfaces. Parameters like brush face length, bristle stiffness, and core material are crucial for ensuring proper hygiene and minimizing contamination risks.

Glass Cleaning: In glass manufacturing and cleaning processes, cylinder brushes with soft, non-abrasive bristles like nylon or natural fibers are used to remove dirt, grime, and residue from glass surfaces without scratching. The brushes are typically mounted on glass washing machines, spinning at high speeds to provide thorough cleaning. Brush diameter, bristle stiffness, and core material are essential factors to consider for effective glass cleaning.

Road Maintenance: Cylinder brushes with robust, wear-resistant bristles, like polypropylene or steel, are employed in road sweeping machines to remove dirt, debris, and loose materials from road surfaces. These brushes often feature large diameters and face lengths to cover wide areas in a single pass. Key parameters include brush diameter, bristle material, and bristle stiffness to ensure efficient road cleaning.

Printing: In the printing industry, cylinder brushes with soft, non-abrasive bristles like nylon or natural fibers are used to clean and maintain printing equipment, such as ink rollers and printing plates. They help maintain consistent print quality by preventing ink buildup and contamination. Brush diameter, bristle stiffness, and core material are critical parameters for effective printing equipment maintenance.

Car Washes: Car washes utilize cylinder brushes with soft, non-abrasive bristles, such as nylon or polypropylene, to clean and scrub vehicle surfaces without damaging paint or finishes. These brushes are typically mounted on automated car wash systems, spinning at high speeds for efficient cleaning. Parameters like brush diameter, bristle stiffness, and core material are essential for effective vehicle cleaning.

Textile Manufacturing: Cylinder brushes with soft bristles, like nylon or natural fibers, are used in textile mills to remove lint, dust, and debris from machinery and fabrics. They help maintain a clean environment and improve the quality of the finished product. Brush diameter, bristle stiffness, and core material are important factors to consider for efficient textile cleaning and maintenance.