Industrial Roller Broom

Keep your roller screen at maximum efficiency using our polyester roller screen brushes. Instead of using softer primers of polypropylene, polyester bristles are used because of their rigidity and strength. Long bristles such as steel wire ppt nylon can be separated from their cores at different intervals. This spacing provides greater cleaning power for multiple screen sizes. Like tubular brooms and wafer cakes, roller brushes have different diameters. The bristles’ length and core length can also be customized as needed. These brushes are specially made for each roller sieve that it cleans.

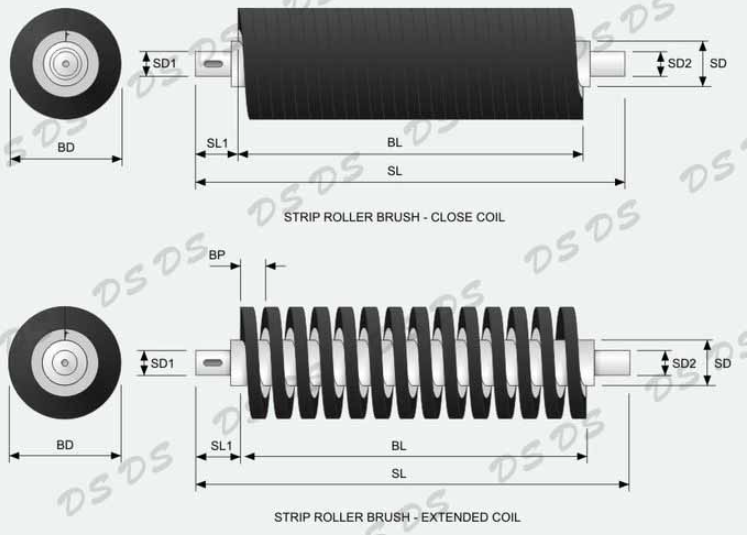

Specifications – Cylindrical Brushes

Polyester PBT: Compared to nylon, polyester is harder, has a better flick effect, has a longer duration, and has a better performance in wet or humid conditions, but at a higher price. Large diameter (over 0.8 mm) polyester starts fatigue in the cylinder main broom after about 120 hours of use. It will not occur on the side brush. Excellent wear-resistant life.

Nylon: Nylon sweeps are not as aggressive as polyester and perform poorly in wet or high humidity conditions. Due to its toughness and excellent long-term wear characteristics, it is often used for external rough surfaces or high-temperature environments. It is generally used in foundries to clean high-temperature debris of up to 150 degrees C. Excellent wear-resistant life.

| Catalog # | Bristle Material | Wire Length (in.) | Brush Part Length (in.) | Wire Diameter | Price |

| 813S | Stainless | 1/2 | 1 1/2 | 0.006 | $1.29 |

| 813SW | Laced SS | 1/2 | 1 1/2 | 0.005 | $4.56 |

| 813B | Brass | 1/2 | 1 1/2 | 0.006 | $1.33 |

| 813H | Horsehair | 1/2 | 1 1/2 | NA | $1.46 |

| 813N | Nylon | 1/2 | 1 1/2 | 0.016 | $1.41 |

JHX offers a complete line of Glass Panels Cleaning Nylon Brushes for a wide range of domestic and foreign washing machines.Each brush is designed to meet customers’ needs and ensure long brush life.

- Surface cleaning and finishing glass panels and mirrors

- Applying finishes and coatings

- Preventing glass splatter in cutting operations

Not sure what exact measurements you need for your custom block brush? Or would you much rather order a brush through a live person over the phone?

Frequently Asked Questions

Read More Industrial Roller Broom