Wire Strip Brush

Stainless steel bar brushes for deburring and polishing Stainless steel channels are used for various functions in production and production environments. Stainless steel strip brushes feature formable metal structural elements called channel bases and stainless steel wire brush fillers that can vary in trim length, density and flexibility.

Stainless steel brushes will be used as product compactors, static reduction devices, hole detectors in insulating coatings, devices for applying wet or dry coatings of substances, or dust collectors to carry away loose material. Conveyor-mounted stainless steel bar brushes will aerate or stabilize product as you move it, or sweep loose debris.

Options for stainless steel brush bar channel substrate selection include:

Galvanized iron – the most economical

Stainless steel – corrosion resistant

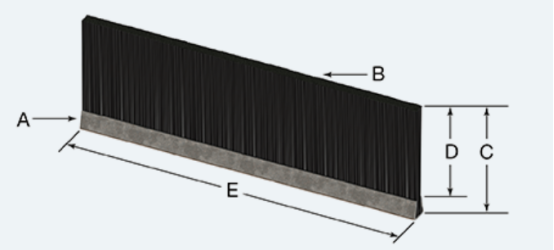

Specifications – Strip Brush

| A mm | B mm | C mm | D mm | E mm | Filler |

| 2.5 | 0.07 | 15 | 35 | 30-2000 | nylon |

| 3 | 0. 1 | 25 | 60 | 30-2000 | nylon |

| 4 | 0.2 | 30 | 80 | 30-2000 | nylon |

| 5 | 0.3 | 50 | 100 | 30-2000 | nylon |

| 6 | 0.4 | 80 | 150 | 30-2000 | nylon |

| 7 | 0.5 | 100 | 200 | 30-2000 | nylon |

| 8 | 0.6 | 160 | 260 | 30-2000 | nylon |

| 9 | 0.7 | 200 | 300 | 30-2000 | nylon |

| 10 | 0.8 | 300 | 500 | 30-2000 | nylon |

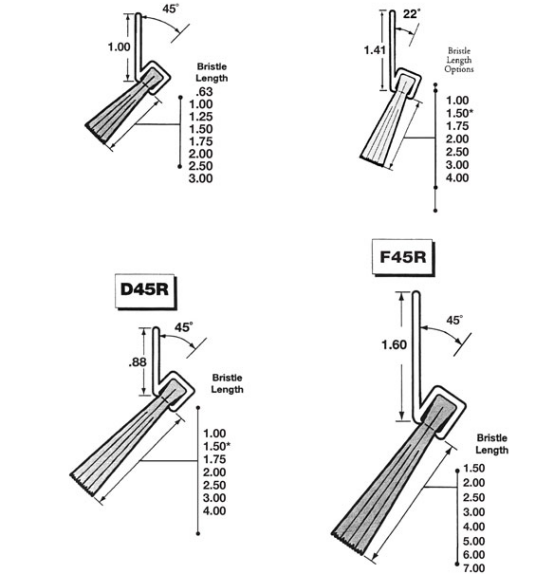

Shaped Strip Brushes

For special applications and on the specific designs of the customer, the cylindrical brushes can be shaped with all types of filament: synthetic, natural, metallic, or mixed.

Given the particular characteristics of performance depending on the profile of the brush, our technical office will advise on the best brush for the type of profile and the filament to be used.

Frequently Asked Questions

Read More Mane Ring Brush