Cylinder brushes are versatile tools used in various industries for various applications. These brushes, often made of durable nylon bristles, are highly effective in cleaning, polishing, deburring, and surface finishing tasks. In this article, we will explore the world of nylon cylinder brushes, exploring their types, applications, benefits, and cleaning procedures.

What are Cylinder Brushes?

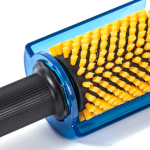

Cylinder brushes are cylindrical-shaped tools with a core surrounded by densely packed bristles. Various industries and applications utilize cylinder brushes for cleaning, polishing, deburring, and surface finishing tasks. These brushes are crucial in maintaining cleanliness and quality across different sectors.

Manufacturers produce cylinder brushes using different materials, and nylon stands out as a popular choice due to its durability and flexibility. The cylindrical shape allows for efficient and consistent contact with surfaces, ensuring thorough cleaning.

Cylinder brushes come in various types, including solid fill, spiral, and strip brushes, each designed to cater to specific cleaning needs. Their versatility and effectiveness make them essential in maintaining cleanliness and quality in numerous industries.

What is Nylon Cylinder Brushes Good for?

Due to their exceptional cleaning capabilities, cylinder brushes find extensive use across multiple industries and applications. Here are some typical applications where these brushes excel:

- Industrial Cleaning: These brushes are ideal for cleaning conveyor belts, manufacturing equipment, and production lines, effectively removing debris, dust, and contaminants.

- Food Processing: The food industry utilizes cylinder brushes for cleaning conveyor systems, sorting and packaging equipment, and ensuring hygiene in food processing facilities.

- Printing: These brushes find application in cleaning printing presses, eliminating ink and paper debris from rollers, and guaranteeing smooth operation and high-quality print output.

- Deburring and Polishing: Nylon brushes with abrasive particles are excellent for deburring metal or plastic parts, as well as polishing surfaces to achieve a smooth and finished appearance.

- Automotive Industry: These brushes find application in automotive manufacturing for cleaning and preparing surfaces before painting, removing rust and corrosion, and cleaning engine components.

Benefits of Nylon Cylinder Brushes

They offer several advantages over other cleaning tools. Here are seven benefits that make them a popular choice:

1. Durability

Nylon bristles are highly durable, ensuring long-lasting performance even in demanding cleaning applications.

2. Chemical Resistance

Nylon is resistant to most chemicals, allowing the brushes to withstand exposure to various cleaning agents without degradation.

3. Flexibility

Nylon bristles provide excellent flexibility, enabling the brushes to adapt to irregular shapes and contours for thorough cleaning.

4. Non-Scratching

Nylon bristles’ soft and fine nature makes them non-abrasive, minimizing the risk of scratching delicate surfaces.

5. Efficient Cleaning

The tightly packed bristles ensure maximum contact with the surface, resulting in efficient and effective cleaning.

6. Versatility

To suit specific cleaning requirements, you can customize cylinder brushes with different bristle lengths, diameters, and densities.

7. Cost-Effective

With their long lifespan and superior cleaning performance, nylon brushes offer a cost-effective solution for various industries.

Where to find nylon cylinder brushes?

If you’re looking for high-quality cylinder brushes, look at cn-brushes.com. This reputable online retailer offers various brushes, including cylinder brushes, with customization options available. With its user-friendly website, international shipping, and responsive customer support, cn-brushes.com is the go-to destination for your cleaning needs.

How to Clean Nylon Cylinder Brushes?

Regular cleaning is essential to maintain the effectiveness and longevity of nylon cylinder brushes. Follow these steps to clean your cylinder brushes effectively:

- Step 1- Remove Excess Debris: Use a brush or compressed air to remove loose debris and dust from the bristles.

- Step 2- Prepare Cleaning Solution: Fill a basin or bucket with warm water and mild detergent or brush cleaner.

- Step 3- Submerge the Brushes: Immerse the brushes in the cleaning solution, ensuring that all bristles are fully submerged.

- Step 4- Agitate Gently: Swirl the brushes in the solution, allowing the cleaning agent to penetrate the bristles and loosen any dirt or residue.

- Step 15- Rinse Thoroughly: Rinse the brushes under running water to remove the cleaning solution and dislodged debris.

- Step 6- Air Dry: Place the brushes in a well-ventilated area or use a fan to dry them thoroughly before storing or reusing them.

FAQs

Can I use cylinder brushes on delicate surfaces?

Yes, these brushes with soft bristles are safe to use on delicate surfaces, as they are non-abrasive and minimize the risk of scratching.

Are cylinder brushes suitable for both wet and dry cleaning?

Certainly! Nylon brushes are versatile and useful in wet and dry cleaning applications.

How often should I clean my cylinder brushes?

The cleaning frequency depends on the cleaning task’s nature and intensity. However, cleaning cylinder brushes after each use is generally recommended to maintain optimal performance.

Last Words

Nylon cylinder brushes are indispensable for efficient and effective cleaning across various industries. Their durability, flexibility, and excellent cleaning capabilities offer numerous benefits and can be easily maintained through regular cleaning. Whether you need to remove debris, polish surfaces, or deburr parts, cylinder brushes are the go-to solution for impeccable results.