What are Rotary Brushes For?

Rotary brushes, also known as rotary brush tools, are specialized brushes that are used for a variety of industrial applications. These brushes are designed to rotate at high speeds and can be attached to various power tools, such as angle grinders, drill presses, and bench-top motor tools. The purpose of rotary brushes is to clean, deburr, surface-prep, finish, or condition various materials and surfaces. They are commonly used in metalworking, woodworking, automotive, and other industries where surface finishing is important. The versatility of rotary brushes makes them a valuable tool for many different applications, and they are essential for achieving high-quality finishes on various materials.

Definition of Rotary Brushes

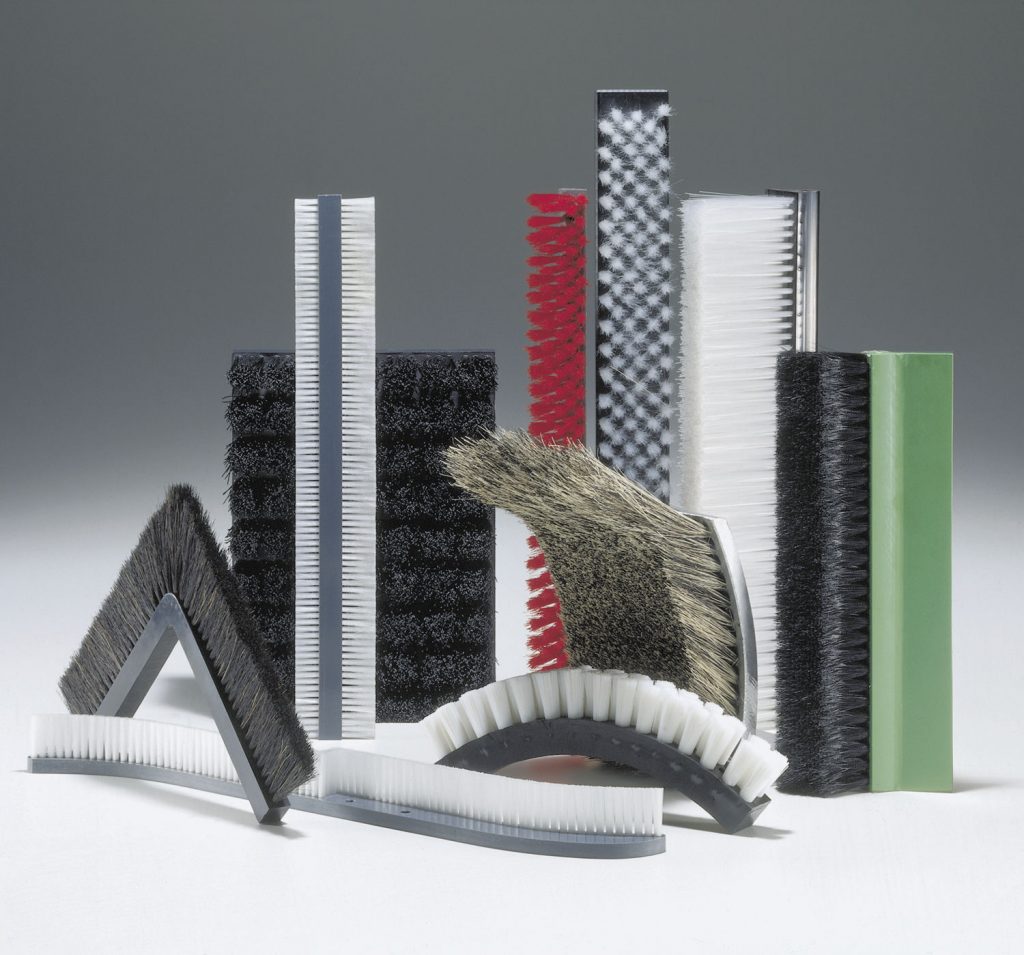

Rotary brushes are industrial tools that consist of a central shaft with bristles or filaments attached to them. The shaft is usually powered by an electric motor and rotates at high speeds, causing the bristles to spin around their axis. These brushes come in various shapes, sizes and materials depending on their intended use.

The main purpose of rotary brushes is to clean, deburr, prepare or finish surfaces. They can be used for removing rust, paint, scale or other surface contaminants from metal parts; smoothing out rough edges and burrs; preparing surfaces for painting or coating; polishing metals or plastics; blending weld seams; cleaning pipes and tubes; scrubbing floors and carpets…the list goes on!

There are several types of rotary brushes available based on the material used for the bristles – wire (steel or brass), nylon, abrasive filament (silicon carbide), natural fiber (horsehair), etc. Each type has its own unique properties that make it suitable for specific applications.

Rotary brushes are versatile tools that offer efficient solutions to many surface processing challenges faced by industries today. Their ability to adapt to different tasks makes them a valuable addition to any manufacturing setup looking for faster production rates and improved quality control.

Types of Rotary Brushes

Rotary brushes come in different types to suit various applications, and each type has unique features that make it suitable for specific tasks. The four most common types of rotary brushes are wire, nylon, steel, and brass.

Wire rotary brushes are made from high-tensile steel wire and can be used on a wide range of materials. They are designed to remove tough rust, paint, weld slag, and other stubborn contaminants from metal surfaces.

Nylon rotary brushes have nylon fibers that make them gentle enough to use on delicate surfaces such as glass or plastic without causing damage. They are perfect for surface preparation before painting or coating.

Steel rotary brushes have carbon-steel filaments that provide excellent cutting power while still being flexible enough to conform to the contours of the workpiece. These brushes can remove heavy rust and corrosion from metals quickly.

Brass rotary brushes offer a softer touch than their counterparts because they contain non-sparking brass filaments. This feature makes them ideal for use in hazardous environments where sparks could cause explosions or fires.

When choosing which type of brush is best suited for your application, you should consider several factors such as the material you need to clean or process; surface condition requirements; brush diameter and configuration options available; fill type (material), among others.

Custom Rotary Brushes

JHX specializes in providing custom Rotary Brushes tailored to meet your specific needs. Rotary Brushes come with various parameters that allow you to customize them according to your specific application needs.

Applications of Rotary Brushes

Rotary brushes have been widely used in various industries due to their versatility and effectiveness. They are designed to perform a variety of tasks, from cleaning and deburring to surface preparation, finishing, and conditioning.

One of the primary applications of rotary brushes is cleaning and deburring. These brushes come in different shapes, sizes, materials, and fill types that can be customized based on the type of material being cleaned or processed. Rotary wire brushes are particularly useful for removing rust, paint, scale or other debris from metal surfaces.

Another application of rotary brushes is surface preparation which involves preparing a surface before applying another layer such as paint or coating. The brush’s abrasive properties help create an even finish by smoothing out rough patches while leaving behind a clean surface ready for further processing.

Rotary brush tools also have extensive use cases in surface finishing where they help achieve desired finishes on surfaces like wood, plastic or metal. In addition to achieving different finishes such as polished or satin finish these tools allow you to control how much pressure is applied to the workpiece which helps avoid over-sanding.

Lastly rotary brushes also find their way into manufacturing processes where they play an important role in refining products during production runs through process known as Surface Conditioning. This step involves using specialized abrasive impregnated nylon filament bristles that leave brushed pattern on metals without scratching delicate details

In conclusion rotary brushes are versatile tools suitable for various industrial applications thanks to its flexibility with multiple factors customization allowing it’s application across several manufacturing spheres

Factors to Consider when Choosing Rotary Brushes

When choosing rotary brushes, there are several factors to consider to ensure that the brush will effectively clean or process the targeted material.

Firstly, it is important to assess the material that needs cleaning or processing. Different materials require different types of brushes, and using an inappropriate brush may result in damage to either the material or the equipment being used.

The surface condition and finish requirements should also be taken into account when selecting a rotary brush. Some applications may require a rougher finish than others, while some materials may not tolerate any scratches or scuffs on their surfaces.

Brush diameter and configuration are also essential considerations as they can affect both performance and efficiency during use. A larger diameter brush tends to cover more area quickly, while smaller diameter ones allow for better access in tight spaces.

When selecting a rotary brush fill type, one must consider its compatibility with both the target material and intended application. Nylon bristles are ideal for delicate polishing applications while steel wire brushes work best when dealing with tough rust removal tasks.

By taking these factors into consideration when choosing rotary brushes, you can make sure your tools will perform optimally according to your specific needs.

Conclusion

Rotary brushes are versatile tools that can be used for a variety of cleaning, deburring, surface preparation, finishing and conditioning applications. They come in different types made from various materials to suit the requirements of specific tasks.

When choosing rotary brushes for your application, it’s important to consider factors such as the material to be cleaned or processed, surface condition and finish requirements, brush diameter and configuration as well as brush material and fill type.

By selecting the right rotary brush for your needs and using it correctly with proper safety precautions in place, you can achieve optimal results while also prolonging the lifespan of your equipment.

-

Cylinder Brush for Conveyor Accessory Brush

Cylindrical Brush(For Conveyor Accessory Brush) 75mm diameter Industrial Nylon Roller clean conveyor cylinder brush We have our only factory, the brush size can be customized! Let us know if you have any questions about the cylinder brushes, as soon as possible. name 75mm Industrial Nylon Roller Cleaning Conveyor drum brush size individuation material Nylon, PA6,… View Product…

-

Cylinder Brush Washer

Cylinder Brush Washer Our engineers and experienced customer service staff will work with you to understand the application, the materials to brush, the required surface finish, the operating environment, and the equipment where your nylon cylinder brush will be installed. We will help you determine the appropriate core, shaft, channel size, and brush material, determine… View Product…

-

Cylindrical Brush for Deburring Tubes

Cylindrical Brush (For Deburring Tubes) We supply wire brushes for most plumbing deburrs on the market. We offer various industry-standard wire brushes for any pipe deburr application. Whether you are deburring stainless steel, aluminum, or anything in between, we will offer a wire deburr brush to meet your needs. Wire brush from 8 inches to… View Product…

-

Cylindrical Brush for Flat Glass Cleaning

cylindrical cleaning brushes (For Flat Glass Cleaning) When particularly high cleanliness is required, install the swing cup brush section between the inlet section and the cylinder brushes. JHX offers a complete line of Glass Panels Cleaning Nylon Brushes for a wide range of domestic and foreign washing machines. Each brush is designed to meet customers’ needs and… View Product…

-

Cylindrical Brush for Fruit Peeled Mechanical

Cylindrical Brush(For Fruit Peeled Mechanical) For nylon roller brush sizes can be customized. Clean brush rollers are cheap and of high quality. You can give us the brush size like this: product name Mechanical fruit peeled cylinder brush size The brush size is customizable! directly heated cathode 0.25 mm nylonOr according to your request material… View Product…

Related Brush Products

read More Rotary Brushes