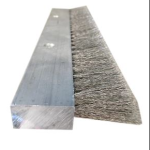

Strip brushes, also known as sealing or sweeping brushes, are versatile tools used in various industries. These brushes have flexible metal or plastic backing and tightly packed bristles. Strip brushes are designed to seal gaps, remove debris, apply coatings, and perform various other tasks.

This article will explore the uses and importance of industrial strip brushes, provide tips on selecting the right brush, and explain how to properly clean them for optimal performance.

What is Strip Brushes?

Strip brushes consist of a backing material, typically metal or plastic, with evenly spaced bristles attached, making them specialized tools. Depending on the intended application, strip brushes utilize bristles made from nylon, polypropylene, natural fibers, or metal wire. Strip brushes come in various sizes, shapes, and configurations to accommodate different requirements.

The Use of Strip Brushes

Strip brushes find applications across multiple industries due to their versatility. Here are some common uses of strip brushes:

-

Sealing

Strip brushes seal gaps and prevent the entry of dust, moisture, air, or pests. They are often employed in doors, windows, conveyor systems, and equipment enclosures.

-

Cleaning and Deburring

The bristles of strip brushes effectively remove dirt, debris, or burrs from surfaces or conveyor belts, ensuring smooth operation and product quality.

-

Applying Coatings

In industrial processes, strip brushes find application in the even and precise application of coatings like paint or lubricants. They aid in achieving a uniform layer, reducing waste, and enhancing efficiency.

-

Conveyor Belt Systems

Conveyor systems benefit from installing strip brushes, as they effectively clean and remove loose materials from the belt surface, enhancing performance and preventing material contamination.

-

Draft Control

Using Strip brushes in HVAC systems to control drafts by sealing gaps around air vents, ducts, or windows, improving energy efficiency and comfort.

Importance of Industrial Strip Brushes

Here are five key reasons why industrial strip brushes are essential:

Reason 1: Efficiency and Productivity

Strip brushes enhance operational efficiency by minimizing downtime caused by machinery malfunctions, ensuring smooth material flow, and reducing maintenance needs.

Reason 2: Cost Savings

Properly installed strip brushes help minimize energy loss, prevent material wastage, and reduce the need for repairs or replacements, resulting in long-term cost savings.

Reason 3: Quality Assurance

Strip brushes aid in maintaining product quality by effectively removing debris, controlling contamination, and ensuring consistent application of coatings or sealants.

Reason 4: Safety Enhancement

Strip brushes contribute to a safer work environment by reducing the risk of accidents caused by loose materials, tripping hazards, or improper sealing.

Reason 5: Versatility

Industrial strip brushes offer a wide range of applications and allow for customization to suit specific needs, ensuring optimal performance in diverse industries and processes.

How to Choose the Right Strip Brush?

When selecting a strip brush, consider the following factors to ensure the best fit for your application:

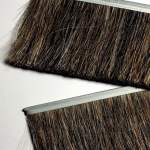

Bristle Material

Choose a bristle material that matches your specific requirements, such as nylon for general-purpose use, stainless steel for heavy-duty applications, or natural fibers for sensitive surfaces.

Backing Type

Select a backing material (metal or plastic) based on durability, flexibility, and compatibility with your equipment or application.

Size and Configuration

Determine the appropriate length, width, and density of the bristles, as well as the brush shape, to achieve optimal performance and coverage.

Consult Experts

To make an informed decision, seek advice from a reputable online retailer like cn-brushes.com, a leading known for its wide range of high-quality industrial strip brushes.

Cleaning Strip Brushes

Regular cleaning is essential to maintain the performance and longevity of your strip brushes. Follow these steps for effective cleaning:

- Remove the Brush: Carefully detach the strip brush from its mounting or holder.

- Shake Off Loose Debris: Gently shake the brush to dislodge any loose debris or particles.

- Rinse with Water: Rinse the brush under a stream of lukewarm water to remove dirt and residue. Avoid using boiling water, as it may damage the bristles.

- Use Mild Detergent: Apply a small amount of mild detergent to a soft brush or cloth, and gently scrub the bristles to remove stubborn stains or buildup.

- Rinse and Dry: Thoroughly rinse the brush with water to remove any detergent residue. Shake off excess water and allow the brush to air dry completely before reinstalling it.

FAQs:

How often should I clean my strip brushes?

The frequency of cleaning depends on the nature of your application. Generally, it recommends cleaning strip brushes at least once every few months or whenever you notice visible dirt or buildup.

Is it possible to customize strip brushes for specific applications?

Yes, it is possible to tailor strip brushes to meet specific requirements. Reputable suppliers like cn-brushes.com offer customization options, including bristle material, size, density, and backing type.

Are strip brushes suitable for outdoor use?

Strip brushes are often used outdoors, thanks to their sealing properties and resistance to environmental elements. However, selecting the appropriate bristle and backing materials is crucial to ensure durability and longevity in outdoor applications.

Last Message

Industrial strip brushes are invaluable tools used across various industries for sealing, cleaning, applying coatings, etc. Understanding these brushes’ uses, importance, and proper maintenance is crucial for achieving optimal performance and efficiency.

By following the guidelines in this article and relying on reputable suppliers like cn-brushes.com, you can confidently choose the right strip brush for your needs and keep them clean for long-lasting effectiveness.