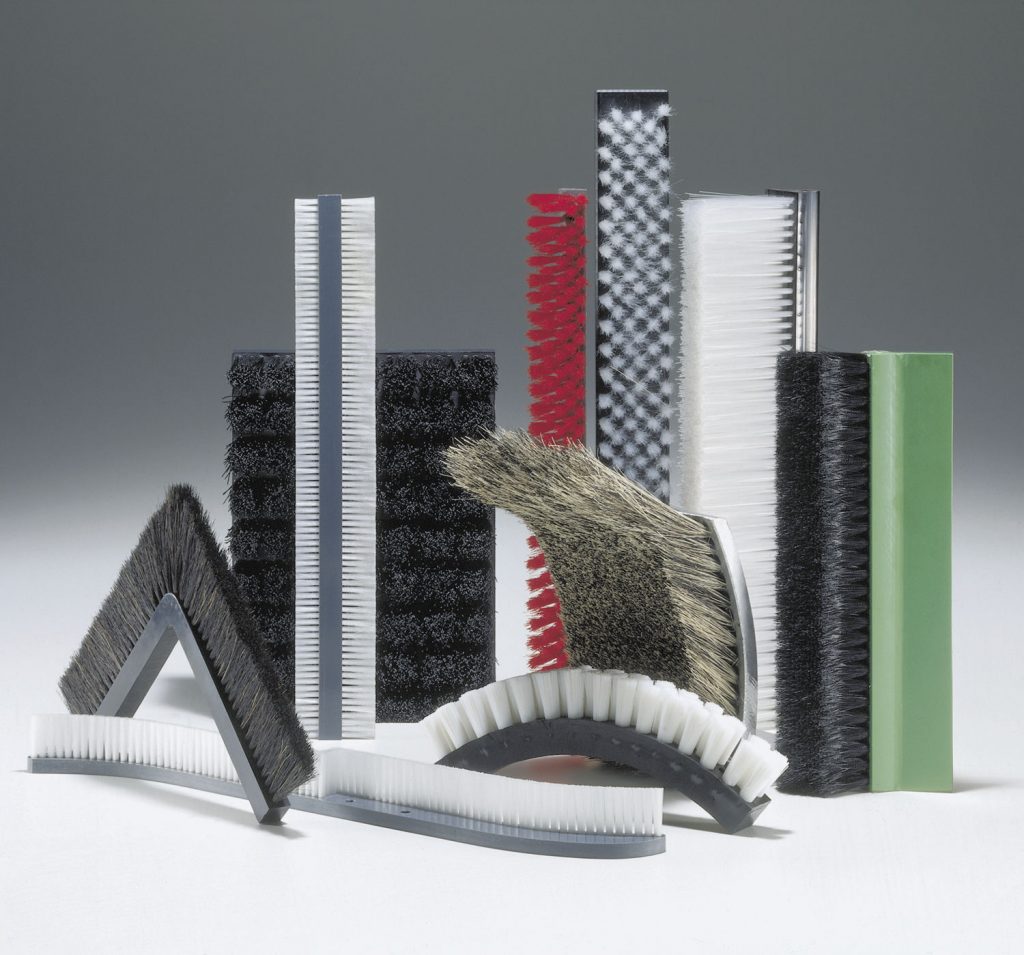

Explore the various applications of strip brushes in sealing gaps across multiple industries, including conveyor systems, door seals, cable management, and HVAC systems. Learn about the importance of selecting the appropriate specifications and materials to ensure optimal performance and durability in each specific use case.

Door & window seals

Usage: Strip brushes are used to seal gaps around doors and windows to prevent drafts, reduce noise, and prevent dust or debris from entering.

Common Specifications: Typically, these strip brushes have a brush length of 1-4 inches, and the overall length depends on the door or window size.

Common Materials: Nylon or polypropylene bristles are commonly used for their durability and weather resistance, while the backing can be made of aluminum or stainless steel.

Conveyor Belt Cleaning

Usage: Strip brushes are utilized to remove debris and dust from conveyor belts, preventing contamination and ensuring smooth operation.

Common Specifications: Brushes with 1-3 inches in brush length and custom overall lengths to match the conveyor width are common in this application.

Common Materials: Nylon, polypropylene, or abrasive bristles like silicon carbide are used, depending on the belt material and debris type. The backing is often made of galvanized or stainless steel.

Cable management

Usage: Strip brushes help keep cables organized and protected from dust or damage in industrial settings.

Common Specifications: These brushes generally have a brush length of 1-2 inches and an overall length tailored to the cable management system.

Common Materials: Nylon or polypropylene bristles are preferred for their flexibility and durability, while the backing can be made of aluminum or stainless steel.

Machinery and equipment

Usage: Strip brushes are mounted on machinery and equipment to seal gaps, minimizing wear and reducing maintenance requirements.

Common specifications: Bristle lengths usually range from 0.5 to 3 inches, with strip lengths varying based on the size of the machinery or equipment.

Common materials: Nylon, polypropylene, and stainless steel are often used for their durability, chemical resistance, and temperature resistance, depending on the specific application requirements.

HVAC systems

- Usage: Strip brushes are installed in air ducts and vents to seal gaps and improve the efficiency of heating, ventilation, and air conditioning systems.

- Common specifications: Bristle lengths typically range from 1 to 3 inches, with strip lengths varying based on the size of the ducts and vents.

- Common materials: Nylon, polypropylene, and Tampico fiber are popular choices due to their heat resistance, moisture resistance, and chemical compatibility.

When selecting the appropriate strip brush for a specific application, it is essential to consider factors such as temperature, chemical exposure, and environmental conditions. Customization options are available to accommodate unique requirements, allowing strip brushes to be tailored to the precise needs of each application.

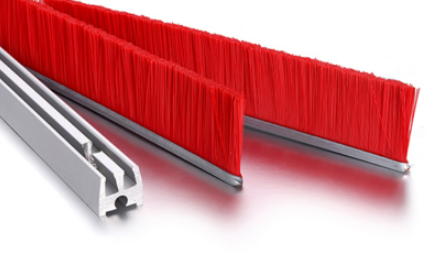

Custom Strip Brushes

JHX specializes in providing custom strip brush services that cater to your unique requirements. Our versatile strip brushes are designed with high-quality materials and are perfect for various applications.

By choosing the correct specifications and materials, strip brushes can provide effective gap sealing and protection across a wide range of industries and use cases.

Strip Brush Related Article

Related Brush Products

Read More Strip Brushes in Sealing