In commercial and industrial cleaning, coil brushes are crucial. They support several sectors in maintaining order and efficiency. These brushes perform a multitude of functions, including filth removal and precise execution of sensitive tasks. They can do a variety of jobs and are resilient and adaptable. In industries including auto shops, food plants, and manufacturers, coil brushes are essential. Let’s examine the importance of coil brushes and what is the best coil brush.

What is a Coil Brush?

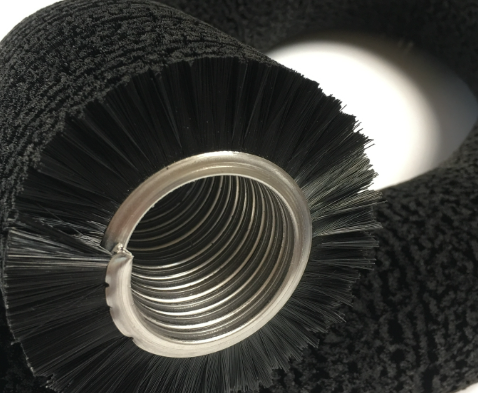

To put it simply, a coil brush is a cylindrical brush with bristles twisted around a core in a spiral pattern. Because of their flexibility and endurance, coil brushes are useful for a variety of applications. There are several varieties of them, such as tufted coil brushes, twisted wire coil brushes, and strip brushes.

How are Coil Brushes Used?

- Cleaning and Deburring: Coil brushes are an essential tool in production and maintenance because of their exceptional ability to clean surfaces and get rid of undesired residues.

- Conveyor Systems: In sectors such as packaging and material handling, these brushes efficiently direct and clean items on conveyor belts, guaranteeing seamless operations.

- Gasketing and sealing: Compressed coil brushes provide strong seals that stop leaks and regulate material flow.

- Weather Stripping: To provide insulation and stop drafts, coil brushes serve a purpose in weather stripping applications in both cars and residences.

Types of Coil Brushes

Coil brushes are the unsung heroes of many industries; there are several varieties, each designed for a particular need. Here are different variants that meet a range of purposes.

1. Strip Brushes: The Workhorse of Cleaning

What: Strip brushes are dense and efficient cleaning tools made of tightly packed bristles linked together by a metal tube.

Where: Perfect for deburring surfaces, closing gaps, and cleaning conveyor belts during industrial operations.

Why: They are great for heavy-duty cleaning jobs because of their robust build and compact form.

2. Tufted Coil Brushes: Precision and Versatility in One

What: The tufts of bristles of tufted coil brushes enable more flexibility and precise cleaning.

Where: Often used in sensitive areas such as electronics production, where it is necessary to clean thoroughly yet gently.

Why: Because of their tufted design, which gives them a gentler touch, they work well on surfaces.

3. Twisted Wire Coil Brushes: Rigidity for Tough Tasks

What: The bristles of twisted wire coil brushes are tightly coiled around a core wire to form a sturdy and strong structure.

Where: Suitable for heavy-duty tasks including surface preparation, rust removal, and welding cleaning.

Why: They are strong due to the twisted wire construction, which makes them useful for removing tough pollutants and debris.

4. Spiral Brushes: Flexibility Meets Efficiency

What: Consisting of continuously coiled bristles, spiral brushes offer flexibility and adaptation to a variety of forms and surfaces.

Where: Often utilized in industrial settings to clean, polish, and finish the surfaces of oddly shaped products.

Why: Their spiral form makes them suitable for a variety of complex cleaning chores by ensuring equal contact with surfaces.

5. Cup Brushes: Conical Precision in Cleaning

What: Cup brushes offer control and precision because of their conical brush shape and arrangement of bristles.

Where: Perfect for cleaning machinery and equipment’s corners, edges, and difficult-to-reach places.

Why? Because of their cup form, which enables concentrated cleaning, they are effective in intricate tasks where precision is crucial.

Factors to Consider When Choosing a Coil Brush

Several things must be taken into account when selecting the ideal coil brush to guarantee peak performance in your particular application. Now let’s examine the key elements that need to be carefully considered when navigating the coil brush market.

Material Considerations: The Backbone of Performance

It’s important to choose the appropriate material for your coil brush. Nylon, horsehair, and metal brushes are common choices that meet various cleaning and application requirements.

Nylon Bristles: These bristles are strong, flexible, and chemical-resistant, making them perfect for all-purpose cleaning.

Horsehair Bristles: Equipped with a soft touch, the horsehair is ideal for applications needing dexterity and attention to detail.

Metal Bristles: Suitable for heavy-duty tasks, metal bristles have a strong cleaning force and can effectively remove tough dirt.

Size and Dimensions: Finding the Perfect Fit

Your coil brush’s effectiveness is directly impacted by its size and proportions. Take into account the following factors to make sure it is appropriate for your application.

Bristle Length: While shorter bristles offer accuracy for little jobs, longer bristles could be appropriate for thorough cleaning.

Core Diameter: A secure fit is certain and needless wear and tear is reduced by matching the core diameter to your equipment.

Application-Specific Requirements: Tailoring Your Choice

There are particular cleaning requirements for many applications and sectors. Taking into account the particular needs of your work guarantees that the coil brush works in perfect harmony with your objectives.

Business Type: Knowing the cleaning requirements specific to your business, whether it be electronics, manufacturing, or food processing, will help you focus your search.

Surface Type: Sturdier choices are better for heavy machines, while softer brushes are possibly needed for delicate surfaces.

Environmental Elements: Taking into account variables such as temperature, humidity, and the existence of corrosive materials guarantees the coil brush’s longevity.

Durability and Maintenance: Longevity Matters

Maintaining the longevity of your coil brush is essential for long-term cost-effectiveness and reliable performance. To determine the lifetime and simplicity of maintenance, consider the following elements.

Material Quality: To ensure durability and resilience in harsh situations, choose high-quality materials.

Resistance to Wear: A sturdy brush can withstand abrasion, lowering the need for maintenance and replacements more frequently.

Cleaning Ease: Throughout its life, a coil brush that is simple to clean will provide maximum performance and hygienic conditions.

What is the best coil brush?

With unmatched quality and performance, the JHX Brush is a strong option in the coil brush market. The JHX Brush is well known for its strength and adaptability, and it works well for a wide range of activities, from precise chores to heavy-duty industrial cleaning. The robust bristles that can tolerate heavy usage are made possible by the carefully chosen materials, which guarantee excellent performance. It is a dependable partner for a variety of cleaning tasks due to its compatibility with various surfaces and cleaning products.

Last Thoughts

Coil brushes are essential equipment in many sectors for maintaining efficiency and cleanliness. They are ideal for a variety of cleaning tasks since they are strong, adaptable, and accurate. Coil brushes are suitable for both delicate and heavy-duty jobs. By using coil brushes, equipment gets kept cleaner longer and performs better. Making wise investments in a hygienic and productive environment for everybody is more important than just picking them.